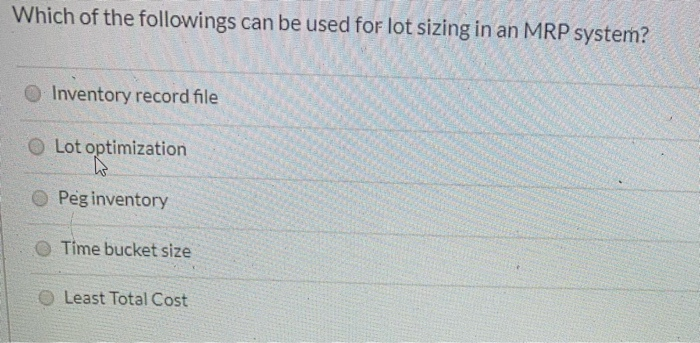

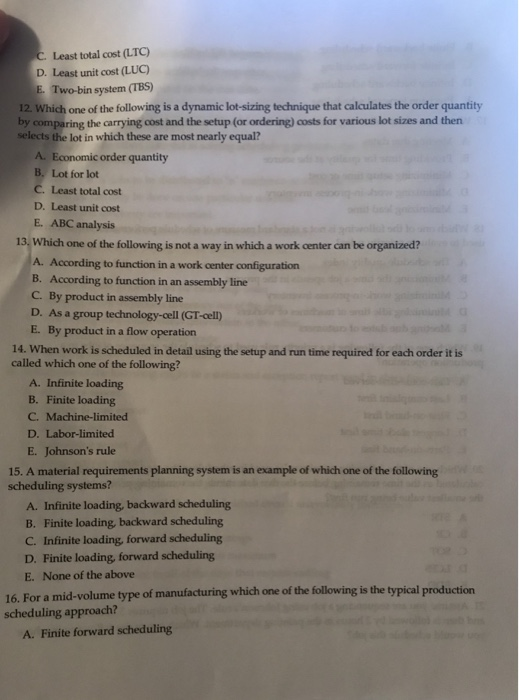

Which Of The Following Can Be Used For Lot Sizing In An Mrp System?

Which of the following can be used for lot sizing in an mrp system?. MRP systems were developed to cope better with dependent demand items. But these requirements without any change may be unsuitable for placing an order or manufacturing. Only one answer is correct A Manual Reorder point planning.

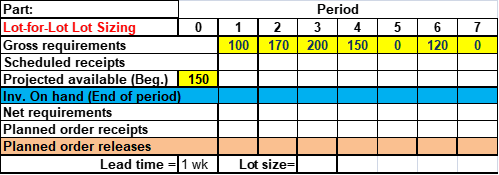

Lot for Lot LFL. Inventory record file E. Materials planning can be set to automatically generate.

B Automatic reorder point planning. Least unit cost D. All of the above.

Forecast based planningcheck D. Answered Aug 7 2019 by. Are important in classifying inventory items and in developing systems to manage items within each demand classification.

Q34 ERP is restricted to being a _____operations system in the country. Information that can be used for other company functions. C MRP logic is based on the logic of uniform continuous demand and item independence.

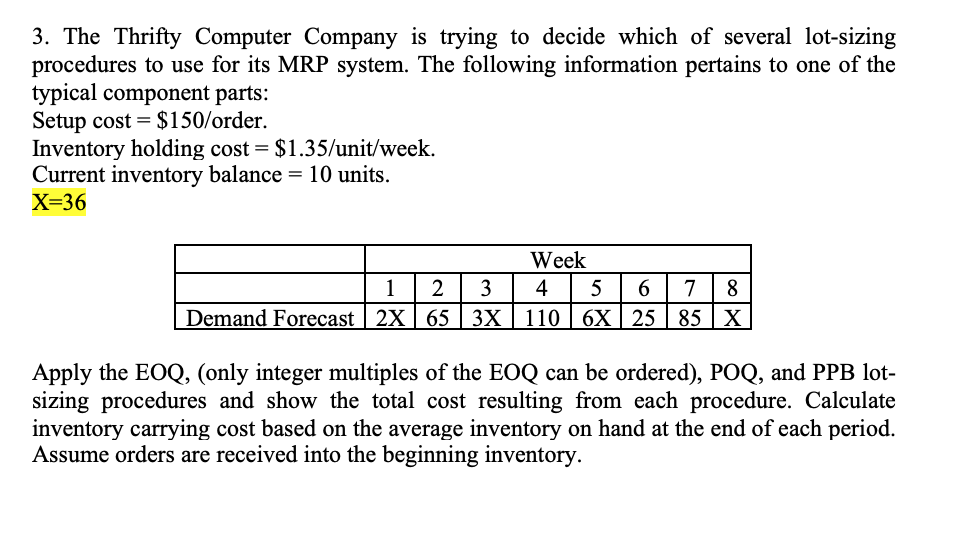

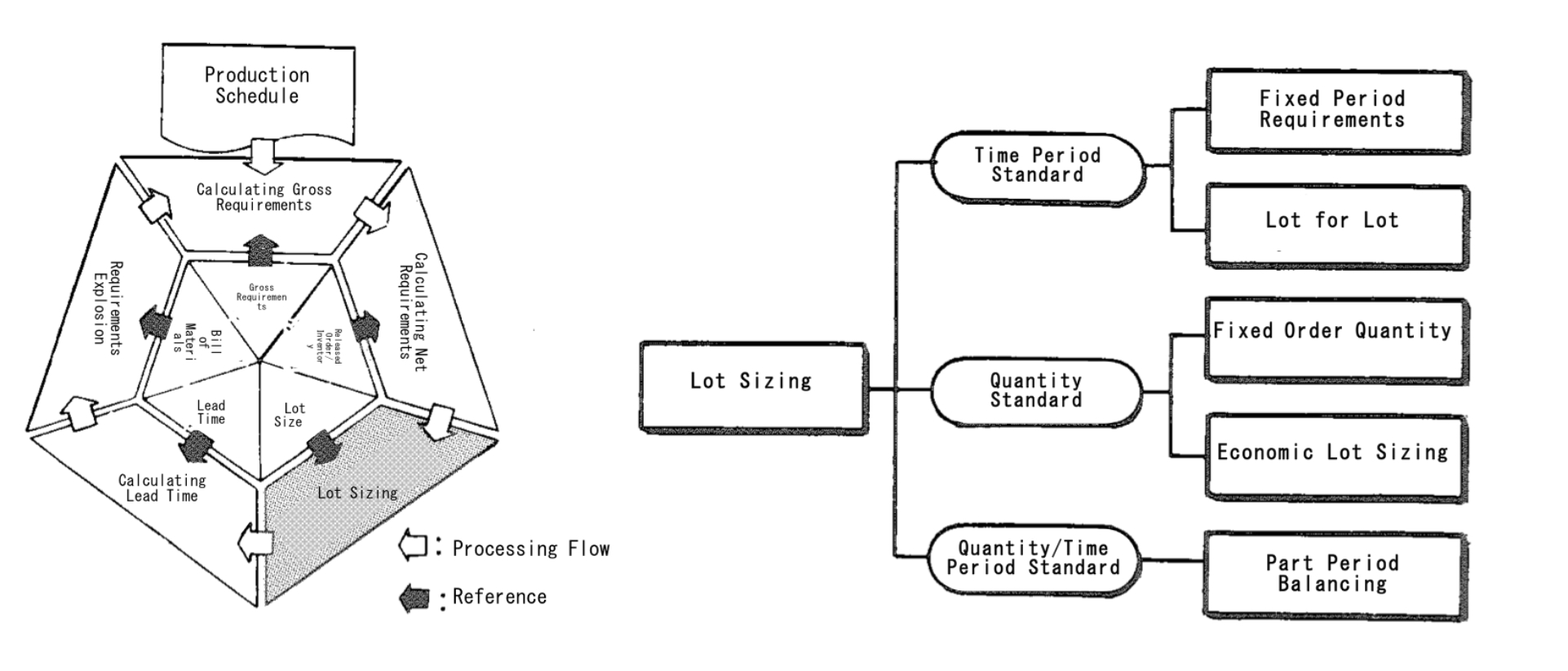

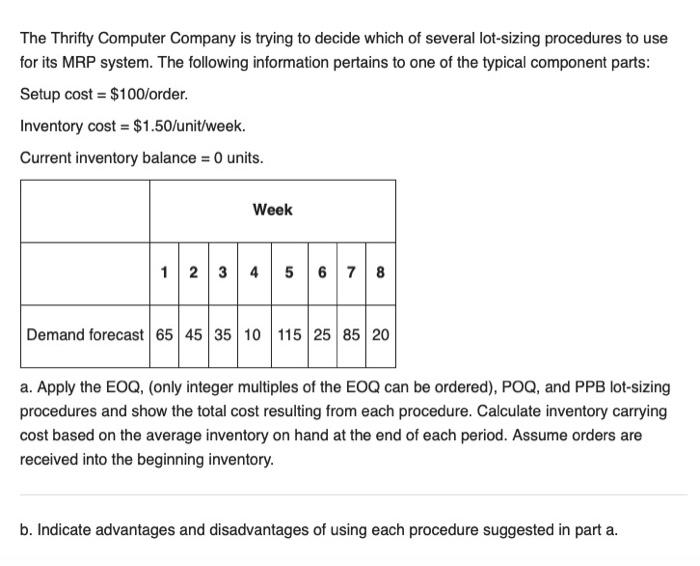

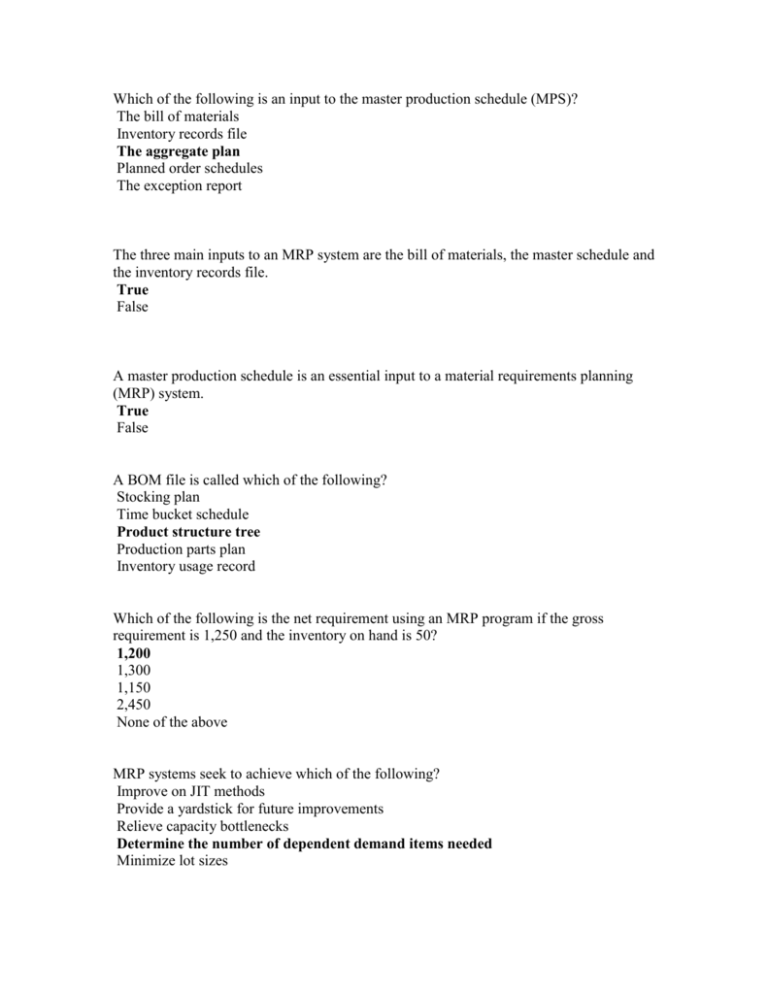

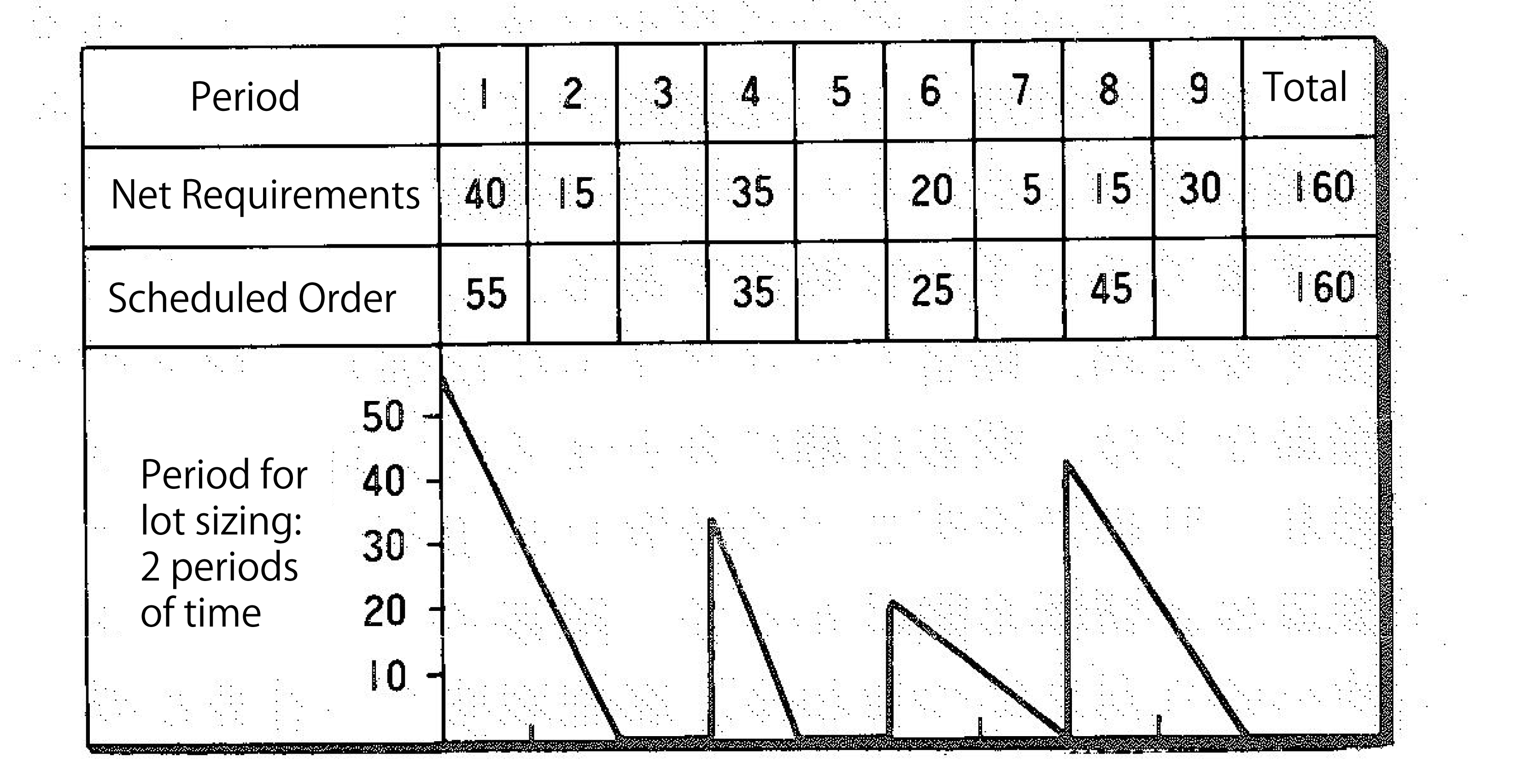

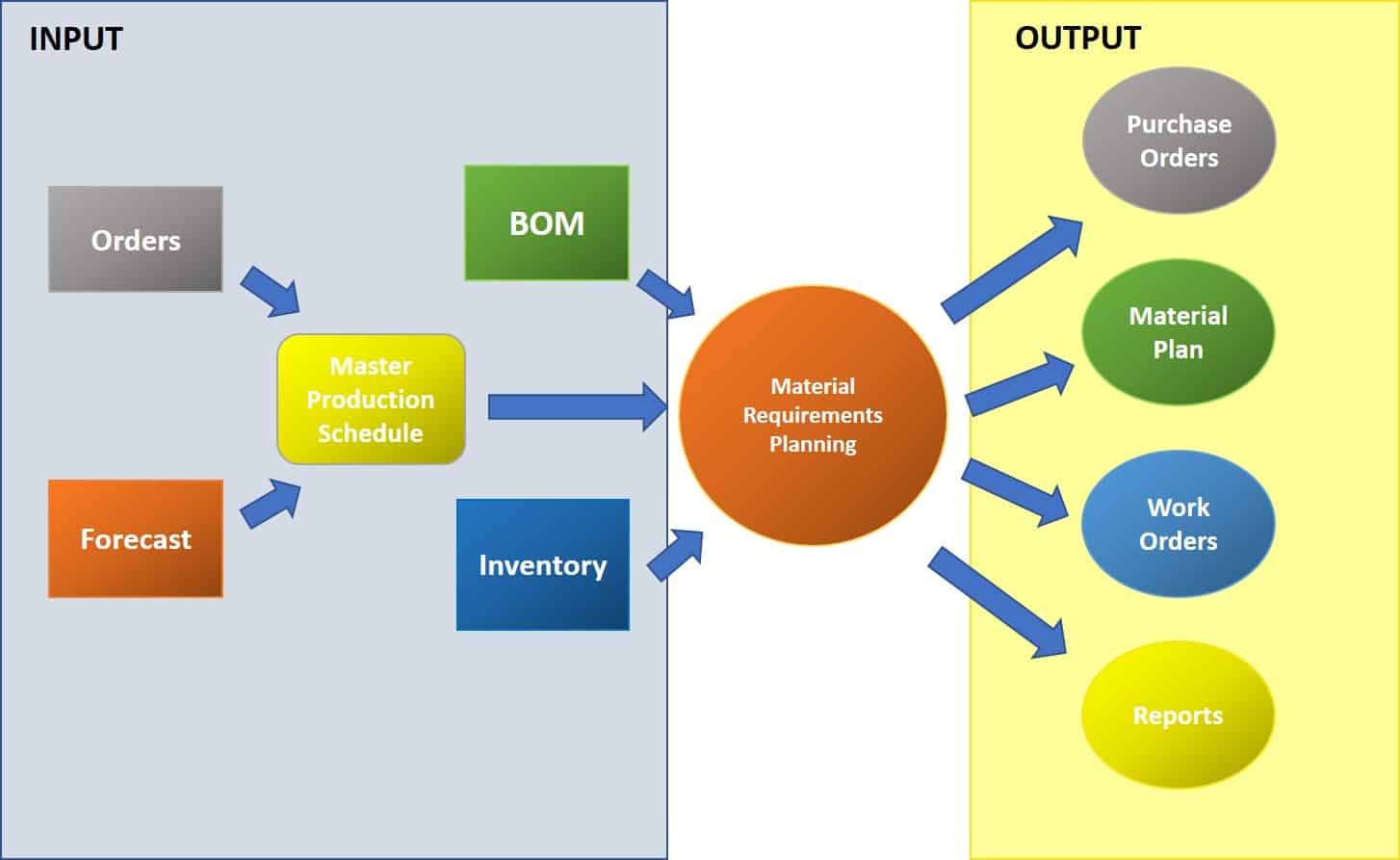

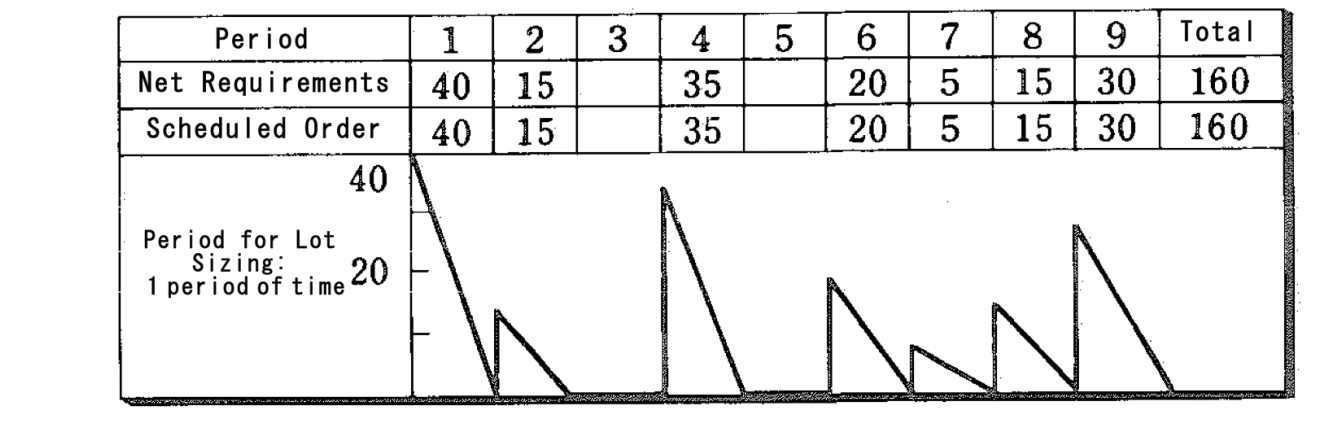

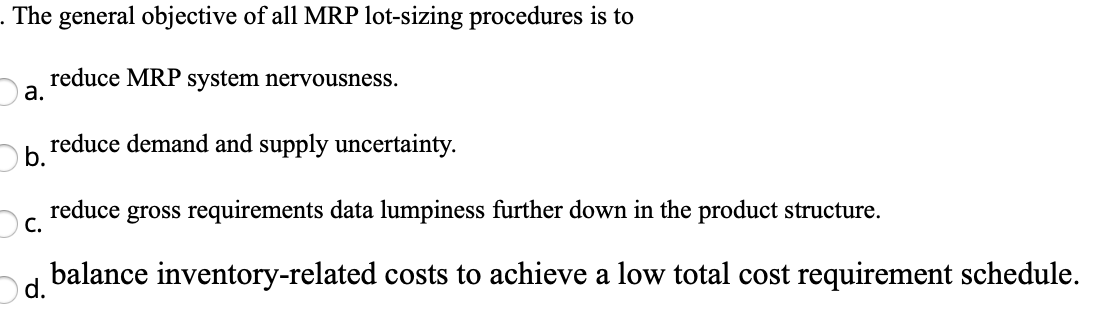

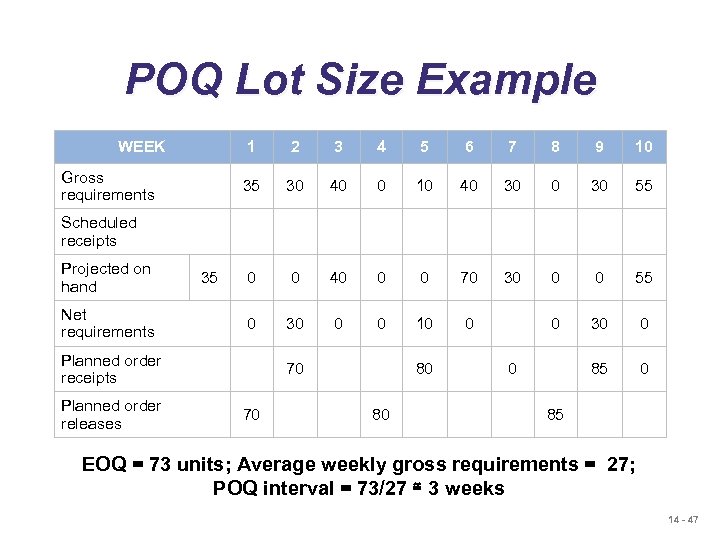

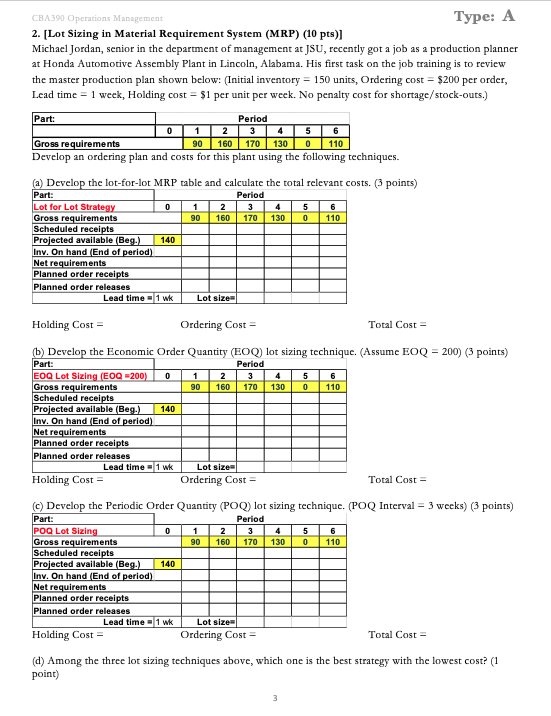

Computer-based material requirements planning MRP systems are used by many businesses to keep track of the resources needed for production or lot sizing and distribution. Static lot-sizing procedures 2. 30An MRP system that provides feedback to the capacity plan master production schedule and production plans is called alot-sizing.

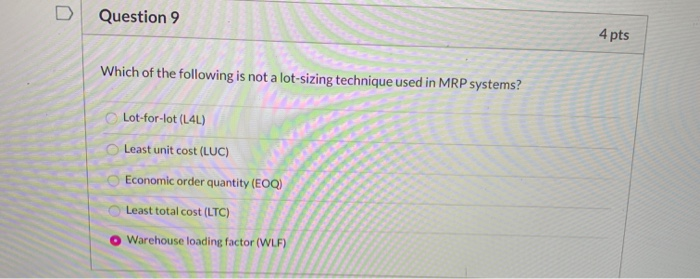

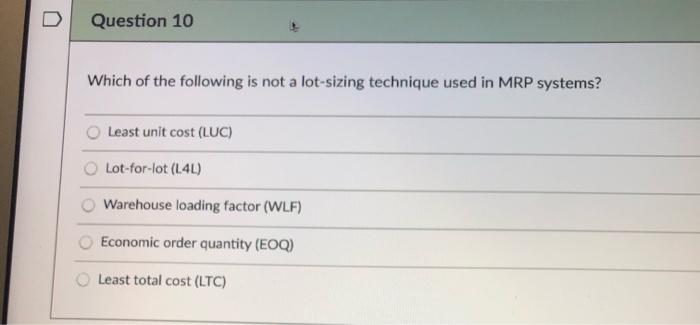

D Time phased planning. Warehouse loading factor WLF E.

But these requirements without any change may be unsuitable for placing an order or manufacturing.

What provides feedback to the capacity plan master production schedule and production plan so planning can be kept valid at all times. Economic Order Quantity EOQ. Materials planning can be set to automatically generate. Order an EOQ or ERL amount. E Storage location MRP. Computer-based material requirements planning MRP systems are used by many businesses to keep track of the resources needed for production or lot sizing and distribution. Storage location MRP Ans. Inventory record file E. When MRP II systems include feedback they are known as.

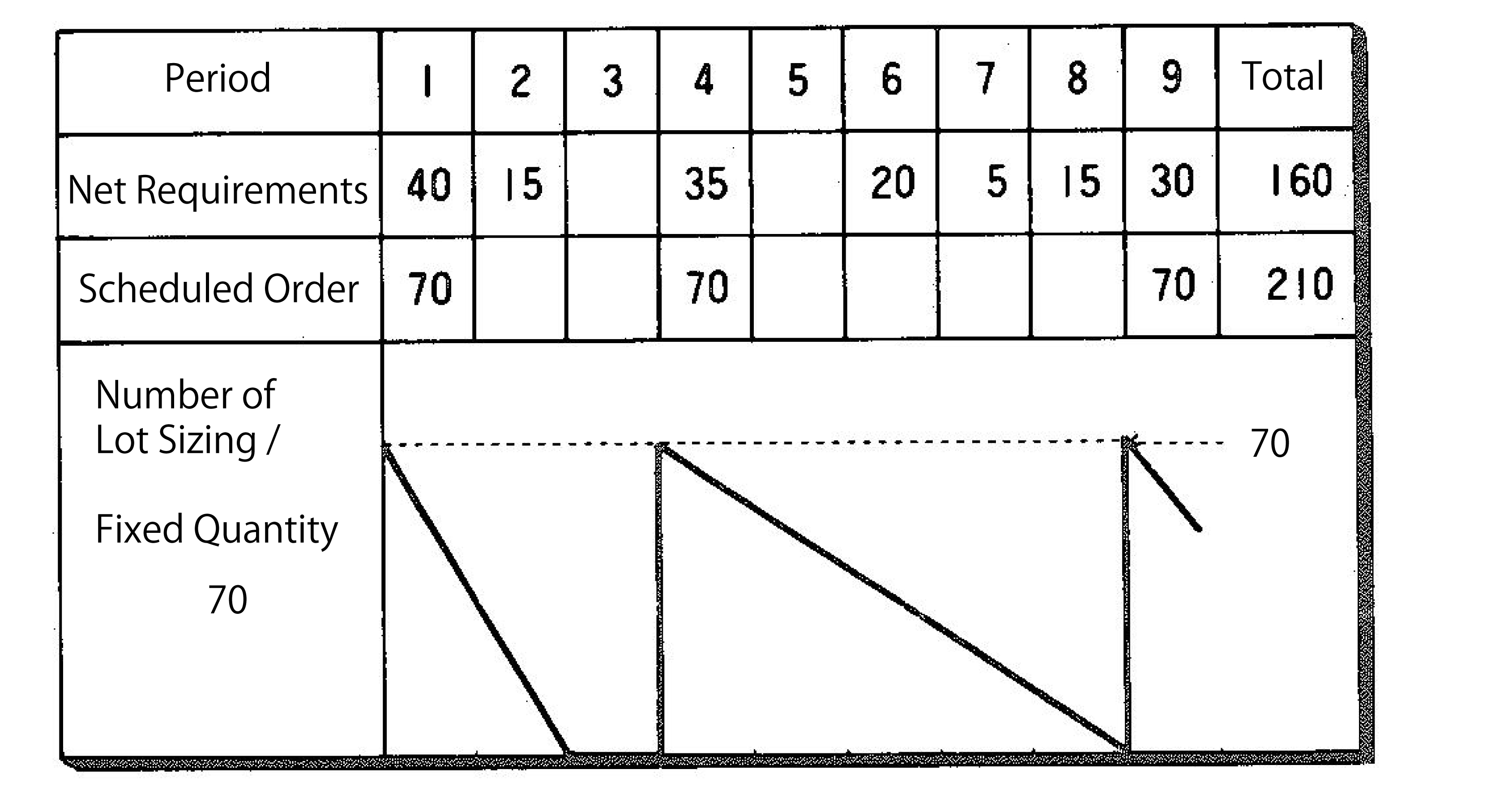

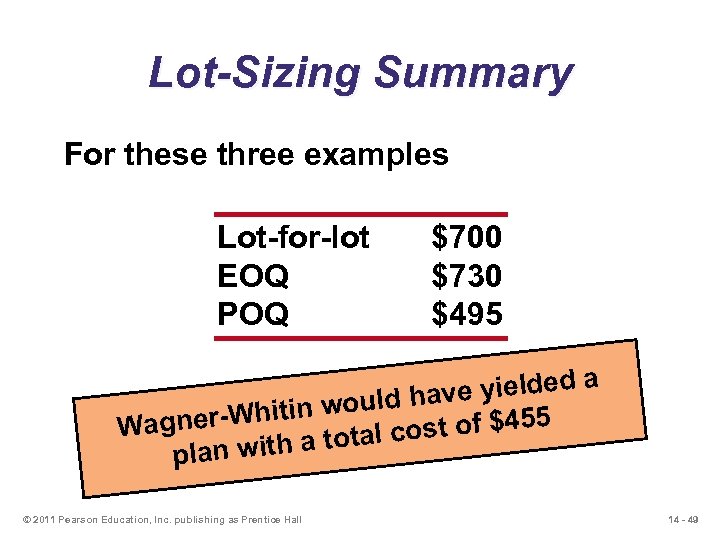

Economic order Quality isnothing yet the bespeak of one EOQ. Which of the following statements about MRP is TRUE. Only one answer is correct A Manual Reorder point planning. B Automatic reorder point planning. Information with cost data. The lot-sizing techniques presented are lot-for-lot L4L economic order quantity EOQ least total cost LTC and least unit cost LUC. Warehouse loading factor WLF E.

Post a Comment for "Which Of The Following Can Be Used For Lot Sizing In An Mrp System?"